Intermodal Facility and Maintenance

- Markets:Housing & Renovation, Shipping & Transport, Warehouse & Buildings

- Country:USA

- Courtesy of:Superior Products International

Project Description

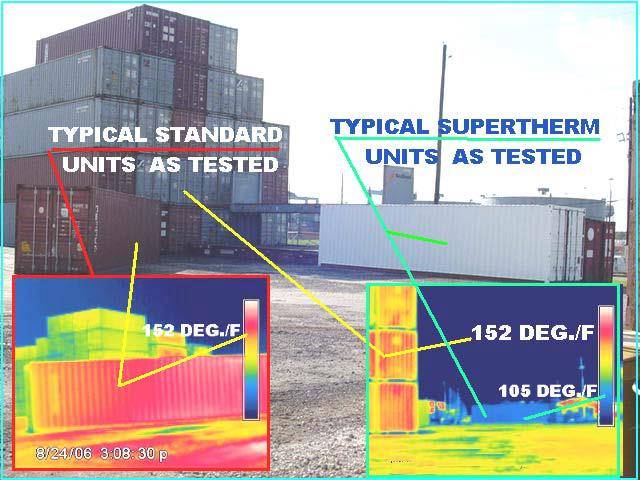

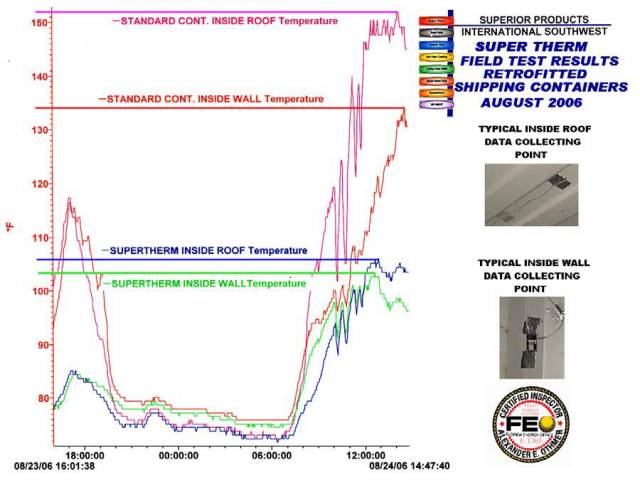

Measurement and Verification Analysis was conducted at the above facility in accordance with the Florida ENERGY CONSERVATION ASSISTANCE PROGRAMS Designation: ECAP-CUL-1-03 Method for Comparing Utility Loads in Structures and Buildings. 2 typical 40FT Standard Containers were used that each had 4,320 data points installed, which simultaneously registered data over a 24 hour test period. One container was treated and the other was not. Infiltration factors around all door seals were equal ( 0 CFM & 0 PA ) and had no adverse effect on the recorded data. All load conducting surfaces on both containers were analysed with recordings at 2 minute intervals.

Coating Solution

The treated test container was coated with SUPER THERM. Application was done using the standard 400μ WFT/250μ DFT application thickness.

Results

Average SITE Weather conditions during the analysis period were as follows:

- High Temperature 97°F / 36.2 °C

- Low Temperature 74°F / 23.3 °C

- Average Wind Speed 3 to 5.5 MPH / 4.8 to 8.8 kmh

- Average UV intensity 99 A+B

THE COMBINED DATA INDICATES THAT THE THERMAL ENERGY NECESSARY TO COOL THE CONTAINER COATED WITH THE SUPER THERM PRODUCT REQUIRED 46% to 52% LESS ENERGY AT THE TIME OF THE SURVEY. RESULTS FURTHER SHOWED:

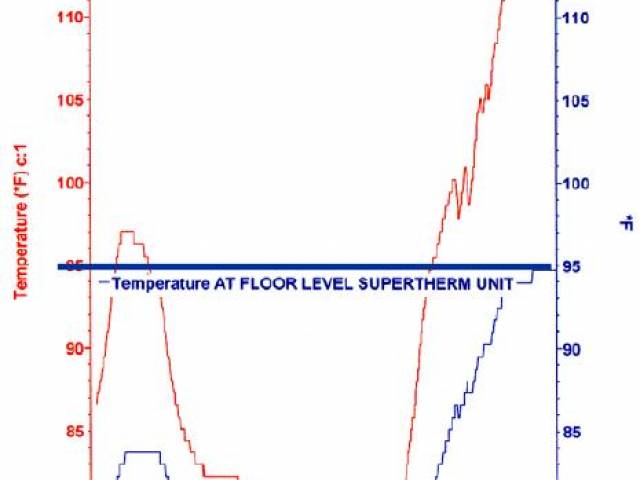

- INSIDE CONTAINER AMBIENT TEMPERATURE 22 DEGREES COOLER

- THERMAL CONDUCTANCE TO OUTSIDE ENVIRONMENT 50% LESS

- EXTERNAL SURFACE TEMPERATURE 47 DEGREES COOLER

- INTERNAL SURFACE TEMPERATURES 37 DEGREES COOLER

- OUTSIDE SURFACE REFLECTIVITY 50% HIGHER

- ULTRAVIOLET ABSORPTION RATE 92% LESS

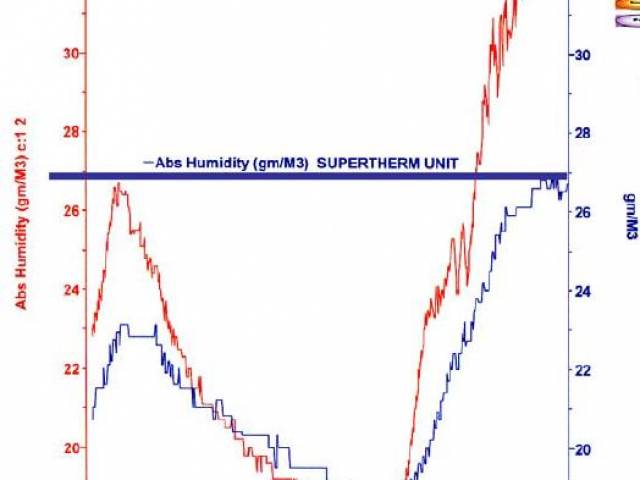

- INTERNAL MOISTURE LEVELS 28.5% DRYER

- SIGNIFICANT REDUCTIONS IN INTERNAL MOISTURE LEVELS WERE ALSO NOTED

Products we used

We remain at your disposal for all enquiries you may have about our wide range of products. Have you not found the solution you are looking for, then let us find one for you.